Applications of Artificial Intelligence in Manufacturing Industries

Shahram Azimi, reporter for Sadaye Sama

Shahram Azimi, reporter for Sadaye Sama

Introduction

Manufacturing industries have always played a fundamental role in economic growth, job creation, and technological development. In recent decades, global competition and rising customer expectations have pushed industries toward adopting advanced technologies. Among these, artificial intelligence (AI) is considered one of the key pillars of Industry 4.0. AI enables intelligent decision-making, prediction, learning, and process automation, and can fundamentally transform traditional manufacturing structures.

Concept of Artificial Intelligence

Artificial intelligence is a branch of computer science that aims to design systems capable of performing tasks that typically require human intelligence, such as learning, reasoning, problem-solving, and pattern recognition. The most important AI subfields used in manufacturing include:

-

Machine Learning

-

Deep Learning

-

Computer Vision

-

Natural Language Processing (NLP)

Applications of AI in Manufacturing

Quality Control and Product Inspection

AI plays a crucial role in quality control and product inspection by using computer vision and deep learning algorithms to detect defects and inconsistencies with accuracy beyond human capability. These systems can continuously inspect every unit and remove defective products before they reach the market, reducing waste and enhancing customer trust in the brand.

Predictive Maintenance

Predictive maintenance leverages AI to manage industrial equipment proactively. Sensor data, such as temperature, vibration, sound, and pressure, is continuously analyzed, and machine learning algorithms identify abnormal patterns to predict potential failures. This reduces unexpected downtime, extends equipment lifespan, lowers maintenance costs, and improves production line efficiency.

Process Optimization

AI-driven process optimization involves intelligent analysis of data from machinery and production stages to achieve maximum efficiency. Machine learning algorithms identify hidden patterns among variables such as time, temperature, speed, and energy consumption to recommend or automatically implement optimal settings. This approach reduces waste, improves product quality, and increases production sustainability.

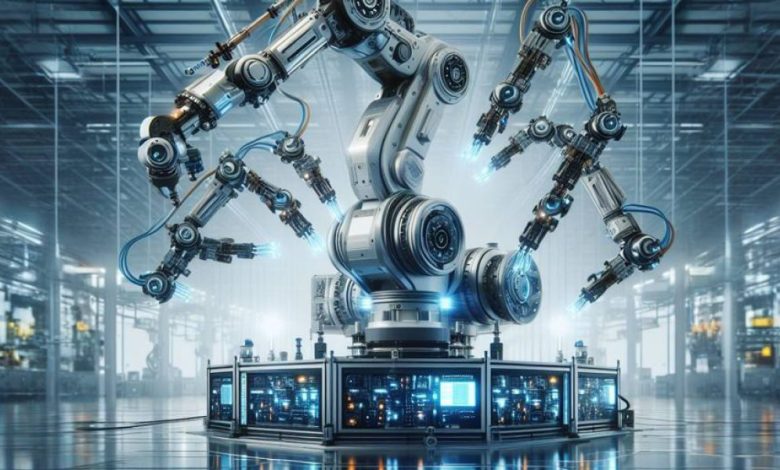

Intelligent Industrial Robots

Intelligent industrial robots have significantly transformed manufacturing processes. Unlike traditional robots, they can learn, adapt to changing conditions, and interact safely with humans. These robots can perform complex, repetitive tasks such as assembly, welding, material handling, and inspection with high speed and precision, increasing efficiency, product quality, and workplace safety.

Supply Chain Management

AI enhances supply chain management by analyzing market demand, inventory levels, lead times, and logistics processes, enabling precise planning and intelligent decision-making. It helps predict demand fluctuations, optimize inventory, reduce logistic costs, speed up delivery, and improve coordination between suppliers and manufacturers, enhancing flexibility and sustainability.

Enhancing Workplace Safety and Health

AI improves industrial safety by detecting hazards and unsafe conditions before accidents occur. Computer vision systems can monitor employee behavior in real-time, identifying non-compliance with safety gear, entry into hazardous zones, or risky actions. Additionally, AI can analyze environmental and health data to improve workplace ergonomics, reduce occupational diseases, and enhance employee satisfaction and productivity.

Benefits of AI in Manufacturing

AI increases efficiency and reduces costs through continuous data analysis and optimized process adjustments, reducing downtime and maximizing production speed. It improves product quality, minimizes human error, and supports intelligent, forward-looking decision-making, making industries more flexible and competitive.

Challenges and Limitations

Challenges include high implementation costs, heavy reliance on accurate data, and shortage of skilled personnel. Human, security, and ethical issues, such as worker resistance, cybersecurity risks, and the absence of clear legal frameworks, also limit widespread adoption.

Conclusion

Artificial intelligence is one of the most transformative technologies in modern manufacturing, enhancing efficiency, reducing costs, and improving product quality. With proper planning, workforce training, and strategic investment, AI can serve as a powerful tool for sustainable industrial development.